Today is my last day as a Network Planning Intern at Air Canada. I started the internship at the beginning of May after my spring semester at Embry-Riddle. I will give a brief summary of my amazing experience.

Aircraft Programs

I began my first two weeks with the Aircraft Programs group. For the first week, I shadowed an aircraft program manager while he was performing his duties of post-delivery activities at an MRO (maintenance, repair, and overhaul) close to Montreal. The airline had just received a brand new Boeing 777-300ER (77W). I tested the seats, tray tables, IFE (inflight entertainment), reading lights, and various galley compartments. The aircraft entered into commercial service a few weeks after.

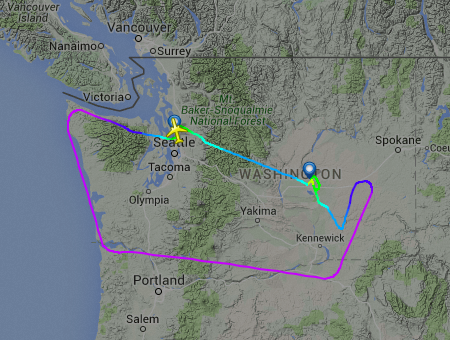

The second week was very exciting as it was my first business trip. I travelled all the way to Seattle because Air Canada was going to take delivery of its 19th and last 77W. I met with the same aircraft program manager at the Boeing Everett Factory. During the first few days, we tested the systems in the aircraft, a bit similar to what we did the previous week in Montreal. We were looking for any defect the plane had before it would be handed off to Air Canada.

My last day in the state of Washington was probably the best. I had the opportunity to fly on the jump seat of the aircraft that was going to be delivered to us the next day. The flight had a duration of about 2h45 and included a touch-and-go and a go-around at Moses Lake (KMWH). Many tests were performed by the flight crew and by mechanics and engineers throughout the flight. The pilots extended the flaps and the slats during the flight. The speed brakes were also deployed for a short period.

I really enjoyed my week at Boeing Everett Factory. I would like to come back to Seattle soon as I did not have the time to truly visit the Emerald City. I learned a lot about Aircraft Programs in the short two weeks I spent with them.

Network Planning

Right after I returned from my trip to the West Coast, I started working in Network Planning. I was part of the long-range team that planned the flight schedule about a year before it is actually flown. I assisted in planning the schedule for North America, which includes Canada, the United States, the Caribbean, and Mexico. Network Planning works closely with other departments such as Intermediate Scheduling, Aircraft Programs, and Revenue Management.

Before I started my internship, I did not know all the items that are taken into account when scheduling a flight. We need to take into consideration aircraft maintenance, turnaround times, flight connectivity at hubs, ideal departure times, flight crew duty time and aircraft types. Our team also analyzes past performance to see if we should add frequencies or put a larger aircraft on a route.

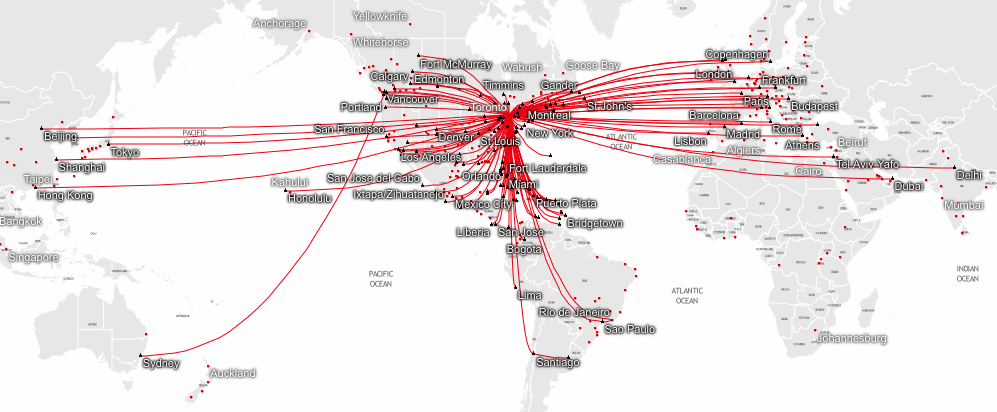

Besides planning future flights, Network Planning consists of expanding the airline’s route network. I had the chance to sit with a few co-workers as they explained me how an airlines evaluate new route opportunities. In one month this summer, we introduced 10 new international routes to Europe, Asia, and Africa. Since May, Air Canada launched 11 routes to the United States.

On June 3, Air Canada launched non-stop service between Montreal and Casablanca (Credits: Air Canada)

I really enjoyed the time I spent this summer in Network Planning. Air Canada has a great team of passionate and energetic aviation enthusiasts. I am proud and honored to have been able to play a small role in planning the schedule for the upcoming seasons.

Summary

I am proud and happy I got the opportunity to get a summer internship at an airline in the aircraft programs and network planning department. This is my second summer in a row doing an internship. Last summer, I worked as an intern in the finance department at Aéroports de Montréal, the authority that manages the Montreal-Trudeau International Airport. So far, I got to experience both the airport industry and the airline industry. After experiencing both, I can definitely say that I belong to the airlines.

Last year on this same day, August 3, I said in my blog: “Now that I have experienced a job in an airport, I would like to go work at an airline in the near future. We’ll see what happens next!” My wish has come true this summer! Next year after I graduate from Embry-Riddle with a Bachelor of Science in Aviation Business Administration, I wish to go work full-time at an airline. In about nine months, we will see if my dream can be fulfilled for a second time!

Until next time!

Nicolas

Contact the author at berniern@my.erau.edu