The last two weeks at the American Airlines Internship was fun, but at the same time somewhat saddening as I would be no longer working as an Intern there. What the future may entail would be my walking down those halls again as a pilot for AA. I can’t wait for that to become a reality. Working at the JFK Flight Office was quite an experience and I could not have asked for a better Internship. I did and saw so much that many pilots around the world may never have the opportunity to see or do and I consider it quite a privilege.

The last two weeks at the American Airlines Internship was fun, but at the same time somewhat saddening as I would be no longer working as an Intern there. What the future may entail would be my walking down those halls again as a pilot for AA. I can’t wait for that to become a reality. Working at the JFK Flight Office was quite an experience and I could not have asked for a better Internship. I did and saw so much that many pilots around the world may never have the opportunity to see or do and I consider it quite a privilege.

The experience was worth the while and I thoroughly had an amazing summer. I met so many people, created so many friendships and networks and got quite a lot of advice from chatting with hundreds of pilots on a daily basis. I would encourage anyone who wants to do an internship to apply for AA! You will be surprised at what you may learn and how it would create the path for your future. Just drop by Career Services and any one of the advisors would be willing to help and advise you.

The experience was worth the while and I thoroughly had an amazing summer. I met so many people, created so many friendships and networks and got quite a lot of advice from chatting with hundreds of pilots on a daily basis. I would encourage anyone who wants to do an internship to apply for AA! You will be surprised at what you may learn and how it would create the path for your future. Just drop by Career Services and any one of the advisors would be willing to help and advise you.

The second to last week I spent a few hours up in the Ramp Control Tower directing some flights and chatting about the upcoming arrivals of AA’s new aircraft. It was a good time and I saw some ‘emergencies’ with getting aircraft out of their gates with minimal delays. The picture to the left is the ramp control tower at JFK. Later that week I was fortunate to spend two half days at Ramp Services. Through this experience I got to drive around the AA Ramp with the Manager on Duty. We went to all the aircraft that were coming into and out of the gates, ensuring that they were being unloaded and loaded promptly, fueled efficiently and catered correctly. We looked at load management for the airplanes and I even got the opportunity to load cargo onto the 777 and 767. It was quite amazing at what goes on in the cargo area for those larger airplanes.

The second to last week I spent a few hours up in the Ramp Control Tower directing some flights and chatting about the upcoming arrivals of AA’s new aircraft. It was a good time and I saw some ‘emergencies’ with getting aircraft out of their gates with minimal delays. The picture to the left is the ramp control tower at JFK. Later that week I was fortunate to spend two half days at Ramp Services. Through this experience I got to drive around the AA Ramp with the Manager on Duty. We went to all the aircraft that were coming into and out of the gates, ensuring that they were being unloaded and loaded promptly, fueled efficiently and catered correctly. We looked at load management for the airplanes and I even got the opportunity to load cargo onto the 777 and 767. It was quite amazing at what goes on in the cargo area for those larger airplanes.

It is all automated and the process is quite easy. The crew chiefs taught me a few things about operating the loading machines and it was just a thrill. I also loaded a few bags onto the conveyor belt to go into the 737 forward cargo area. The picture to the right is from after I unloaded cargo out of the 767.

It is all automated and the process is quite easy. The crew chiefs taught me a few things about operating the loading machines and it was just a thrill. I also loaded a few bags onto the conveyor belt to go into the 737 forward cargo area. The picture to the right is from after I unloaded cargo out of the 767.

While I was on the ramp, I got the opportunity to drive the tow after pushing back an aircraft. That was so much fun! I am really going to miss this internship. The Ramp guys were so welcoming and gave me all the knowledge they could have. I couldn’t be more appreciative. During the week, I also got a tour of Baggage Services. What they do down there is quite amazing. Those conveyor belts form a labyrinth under the terminals and I was so shocked. The bags shoot down, over, under with so much speed like a roller coaster.

While I was on the ramp, I got the opportunity to drive the tow after pushing back an aircraft. That was so much fun! I am really going to miss this internship. The Ramp guys were so welcoming and gave me all the knowledge they could have. I couldn’t be more appreciative. During the week, I also got a tour of Baggage Services. What they do down there is quite amazing. Those conveyor belts form a labyrinth under the terminals and I was so shocked. The bags shoot down, over, under with so much speed like a roller coaster.

If you saw Toy Story 2 where Woody was lost in the conveyor belts, then that was a perfect representation of the system. At the ending of that week I headed to Dallas for a luncheon with the fellow interns. I was also able to receive an ARFF Tour at JFK. They have the most up-to-date technology there. Their fire trucks were state-of-the-art and quite new. The officers gave me a tour of their facility, explained their operation and allowed me to jump into their trucks and drive around a little. Thank you AA!

If you saw Toy Story 2 where Woody was lost in the conveyor belts, then that was a perfect representation of the system. At the ending of that week I headed to Dallas for a luncheon with the fellow interns. I was also able to receive an ARFF Tour at JFK. They have the most up-to-date technology there. Their fire trucks were state-of-the-art and quite new. The officers gave me a tour of their facility, explained their operation and allowed me to jump into their trucks and drive around a little. Thank you AA!

I returned to Dallas the following week for a DFW Tour and the closing luncheon for the Internship. The DFW Tour was fun and quite different from that at JKF and LGA. The operations side of things was more hectic as DFW is our major hub. We toured the Flight Offices, Ramp Control and drove around the Ramp. The picture to the right was from a preflight of a S80 at DFW.

I returned to Dallas the following week for a DFW Tour and the closing luncheon for the Internship. The DFW Tour was fun and quite different from that at JKF and LGA. The operations side of things was more hectic as DFW is our major hub. We toured the Flight Offices, Ramp Control and drove around the Ramp. The picture to the right was from a preflight of a S80 at DFW.

The closing Luncheon was nice, as it was the one time where all the interns were able to be together. The night before a couple of us explored the city of Fort Worth. No better BBQ than in Texas! We had a delicious lunch and then the Vice President of Flight- Captain John Hale gave a heart-warming speech. My last two days were spent at the JFK Flight Office. On the final day I went to a presentation for Flight Services, where I saw booths comparing our products in the different cabins with other world-class carriers, and I must say that AA measures up quite well with the 5-Star carriers. We are a force to be reckoned with.

The closing Luncheon was nice, as it was the one time where all the interns were able to be together. The night before a couple of us explored the city of Fort Worth. No better BBQ than in Texas! We had a delicious lunch and then the Vice President of Flight- Captain John Hale gave a heart-warming speech. My last two days were spent at the JFK Flight Office. On the final day I went to a presentation for Flight Services, where I saw booths comparing our products in the different cabins with other world-class carriers, and I must say that AA measures up quite well with the 5-Star carriers. We are a force to be reckoned with.

When I returned to the Flight Office I was surprised with a farewell party. It was in such a shock, as I wasn’t expecting anything of the sort. The LGA Flight Office closed down for the day and came over to spend time with me on my final day. I was surprised with a really nice lunch, cake, and lots of presents and heart-warming cards and words. I am so fortunate to have worked with such great people. The picture to the left was from my last day at the Flight Office and the one to the right are some of the amazing people of the JFK/LGA Flight Office.

When I returned to the Flight Office I was surprised with a farewell party. It was in such a shock, as I wasn’t expecting anything of the sort. The LGA Flight Office closed down for the day and came over to spend time with me on my final day. I was surprised with a really nice lunch, cake, and lots of presents and heart-warming cards and words. I am so fortunate to have worked with such great people. The picture to the left was from my last day at the Flight Office and the one to the right are some of the amazing people of the JFK/LGA Flight Office.

I am at the LGA Airport headed to CVG right now writing this journal entry. I will keep you posted with one more entry next week about the Procter & Gamble Student Development Program. I am very fortunate for my time at AA. It was a wonderful experience and a great learning opportunity. I would eventually like to fly for this airline because they really do embody all that I believe in, and AA is and will continue to be the American legacy.

I am at the LGA Airport headed to CVG right now writing this journal entry. I will keep you posted with one more entry next week about the Procter & Gamble Student Development Program. I am very fortunate for my time at AA. It was a wonderful experience and a great learning opportunity. I would eventually like to fly for this airline because they really do embody all that I believe in, and AA is and will continue to be the American legacy.

The past two weeks have been amazingly great. I did so much within that period that would probably have spanned the entire internship. I have a new respect for the airline industry and for those who work there. It is a dynamic environment with many people who all work arduously together to ensure a flight is out on-time in the most safest and expeditious manner. Be it baggage services, passenger services, flight service, maintenance, the flight crew or the administrative group, their main aim is towards the common goal of managing an effective airlines and American Airlines has accomplished that.

The past two weeks have been amazingly great. I did so much within that period that would probably have spanned the entire internship. I have a new respect for the airline industry and for those who work there. It is a dynamic environment with many people who all work arduously together to ensure a flight is out on-time in the most safest and expeditious manner. Be it baggage services, passenger services, flight service, maintenance, the flight crew or the administrative group, their main aim is towards the common goal of managing an effective airlines and American Airlines has accomplished that. The week started out with me flying to Dallas for 3 days to partake in a Luncheon and then Simulator Training. I spent four hours in a 737-800 Level D simulator which was divided up into 2 hours in the Captain’s position and the other 2 hours in the First Officer’s position. We had an hour briefing before and after the session. The ‘Sim’ session consisted of normal take-offs and landings, Precision & Non-Precision Approaches, Single-Engine Approaches and Landings, Aborted Take-Offs prior to and at V1, Failures, Fires and In-flight Emergencies, Single-Engine Operations, CAT I, II, III Approaches, RNP Approaches, Drift Down, FMC Operations, Unusual Attitudes, Wind shear Recovery, Missed Approaches, Low Visibility Operations and much more. It was so much fun and I learned a lot about flying large transport category aircraft. Flight Technique Analysis class at ERAU did indeed pay off. CRM is very important also and the FMS Class made me a pro at working the ‘box’.

The week started out with me flying to Dallas for 3 days to partake in a Luncheon and then Simulator Training. I spent four hours in a 737-800 Level D simulator which was divided up into 2 hours in the Captain’s position and the other 2 hours in the First Officer’s position. We had an hour briefing before and after the session. The ‘Sim’ session consisted of normal take-offs and landings, Precision & Non-Precision Approaches, Single-Engine Approaches and Landings, Aborted Take-Offs prior to and at V1, Failures, Fires and In-flight Emergencies, Single-Engine Operations, CAT I, II, III Approaches, RNP Approaches, Drift Down, FMC Operations, Unusual Attitudes, Wind shear Recovery, Missed Approaches, Low Visibility Operations and much more. It was so much fun and I learned a lot about flying large transport category aircraft. Flight Technique Analysis class at ERAU did indeed pay off. CRM is very important also and the FMS Class made me a pro at working the ‘box’. I came back on Wednesday and spent the remainder of the day at LGA. Helped out around the office and caught up with some friends since I haven been spending all my time over at JFK. Later that week I spent half of a day up at the JFK FAA Tower. That was fun, as they gave me a headset to listen in on their communications. So many accents! I got to see a missed approach, a go-around and Emirates A380 land. The air traffic controllers were very much passionate about their jobs and have a lot of fun in the tower. I was able to understand most of their strip markings, procedures and phraseology. Riddle’s Air Traffic Program has been so beneficial and now I can see things not only from a pilot’s perspective but also the controller’s side. The picture to the right is a view from the tower.

I came back on Wednesday and spent the remainder of the day at LGA. Helped out around the office and caught up with some friends since I haven been spending all my time over at JFK. Later that week I spent half of a day up at the JFK FAA Tower. That was fun, as they gave me a headset to listen in on their communications. So many accents! I got to see a missed approach, a go-around and Emirates A380 land. The air traffic controllers were very much passionate about their jobs and have a lot of fun in the tower. I was able to understand most of their strip markings, procedures and phraseology. Riddle’s Air Traffic Program has been so beneficial and now I can see things not only from a pilot’s perspective but also the controller’s side. The picture to the right is a view from the tower. The following week proved to be busier that I expected. Monday I met up with a 767 crew who invited me to preflight with them, program the FMC and hang with them in the cockpit before they were ready to push back. Later that afternoon I spent a few hours with the Flight Service Department. I learned about their operations and then gate hopping with the MOD to ensure the flight attendants were okay, the cabin was ready for departure and the cabin crew was all set for their flight. There is a lot of work that goes into ensuring the plane is well prepared for flight, from cleaning, catering to maintenance. Once again I reiterate the importance that all the employees place on ensuring the planes go out and come in safely, with the best of services.

The following week proved to be busier that I expected. Monday I met up with a 767 crew who invited me to preflight with them, program the FMC and hang with them in the cockpit before they were ready to push back. Later that afternoon I spent a few hours with the Flight Service Department. I learned about their operations and then gate hopping with the MOD to ensure the flight attendants were okay, the cabin was ready for departure and the cabin crew was all set for their flight. There is a lot of work that goes into ensuring the plane is well prepared for flight, from cleaning, catering to maintenance. Once again I reiterate the importance that all the employees place on ensuring the planes go out and come in safely, with the best of services. The next day proved to be so worthwhile. I spent the day traveling to ORD and back just for fun. I hopped on a ferry flight and repositioned it over to ORD. Spent 10 minutes at ORD and then hopped on the next flight to LGA. It was a long day, but one of the best days of the summer. The next day I got up-close and personal with all the airliners that fly into JFK. I spent the day with the General Manager of the Airport. I got a tour of their facilities and then I jumped in their car and drove around the entire field. It was so much fun and I learned a lot from the managing side of things. I went from cargo facilities, to every terminal, runways and taxiways.

The next day proved to be so worthwhile. I spent the day traveling to ORD and back just for fun. I hopped on a ferry flight and repositioned it over to ORD. Spent 10 minutes at ORD and then hopped on the next flight to LGA. It was a long day, but one of the best days of the summer. The next day I got up-close and personal with all the airliners that fly into JFK. I spent the day with the General Manager of the Airport. I got a tour of their facilities and then I jumped in their car and drove around the entire field. It was so much fun and I learned a lot from the managing side of things. I went from cargo facilities, to every terminal, runways and taxiways. Even got to see an airport sign get blown out by jet blast. I was also fortunate to get a tour of the land side of the airport and not only the air side. I was all over the airplanes though, especially the 777-300ER’s, 747-400, A340-600, A380-800. The picture to the right was taken from the approach end of the runway as BA 747 was landing, one of my favorite airplanes of all times. I was even at the end of the departure runway as the planes took off and got jet blasted a few times…. FUN! The pictures below are from the A380 rounds and some jet blast from AA 757:

Even got to see an airport sign get blown out by jet blast. I was also fortunate to get a tour of the land side of the airport and not only the air side. I was all over the airplanes though, especially the 777-300ER’s, 747-400, A340-600, A380-800. The picture to the right was taken from the approach end of the runway as BA 747 was landing, one of my favorite airplanes of all times. I was even at the end of the departure runway as the planes took off and got jet blasted a few times…. FUN! The pictures below are from the A380 rounds and some jet blast from AA 757:

It was an amazing two weeks and I saw, learned and experienced a lot. Now I’m heading into my final two week on the internship then onto Proctor & Gamble for the Student Development Program. Stay tuned for the next entry and fly safe! Keep the blue side up…

It was an amazing two weeks and I saw, learned and experienced a lot. Now I’m heading into my final two week on the internship then onto Proctor & Gamble for the Student Development Program. Stay tuned for the next entry and fly safe! Keep the blue side up… The last two weeks have been probably the best thus far at the American Airlines Internship Program. I have learned, experienced and met so many people that I can now say I have a better understanding of how an airline is managed. From the last journal entry, I spent my 4th July weekend with my family and friend Justin who came to visit me in NYC. We explored the city, toured a bit and went on fun excursions that led us to meeting new and quite interesting people. We even met a representative from Singapore Airlines and the Manager of a NY Museum. We were fortunate enough to get VIP invitations to an art exhibition later that week.

The last two weeks have been probably the best thus far at the American Airlines Internship Program. I have learned, experienced and met so many people that I can now say I have a better understanding of how an airline is managed. From the last journal entry, I spent my 4th July weekend with my family and friend Justin who came to visit me in NYC. We explored the city, toured a bit and went on fun excursions that led us to meeting new and quite interesting people. We even met a representative from Singapore Airlines and the Manager of a NY Museum. We were fortunate enough to get VIP invitations to an art exhibition later that week. Work commenced at the office with Lauretta, Dee, Lorraine, Melissa and the Chief Pilot, Scott Meade. I spent most of the week working on the APU Project, preparing spreadsheets, and charts. These charts would go to Jan Paladino, a 767 FO who works in the Flight Office. From there, the work that I have done goes to the Chief Pilot and then to the Vice-President of Flight, John Hale. I feel very privileged to have an input into such a massive project that makes an improvement in American Airlines. That Friday I worked closely with Jan going around the airport and shutting down Auxiliary Power Units (APUs) on aircraft that have a long ground time. I even stayed an hour after work to continue this, as it was so much fun and exciting. Now I can turn on and off the APUs on the 737, 757, 767 and 777. The pictures to the right and above are from that experience.

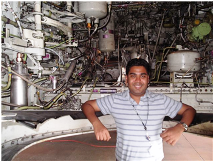

Work commenced at the office with Lauretta, Dee, Lorraine, Melissa and the Chief Pilot, Scott Meade. I spent most of the week working on the APU Project, preparing spreadsheets, and charts. These charts would go to Jan Paladino, a 767 FO who works in the Flight Office. From there, the work that I have done goes to the Chief Pilot and then to the Vice-President of Flight, John Hale. I feel very privileged to have an input into such a massive project that makes an improvement in American Airlines. That Friday I worked closely with Jan going around the airport and shutting down Auxiliary Power Units (APUs) on aircraft that have a long ground time. I even stayed an hour after work to continue this, as it was so much fun and exciting. Now I can turn on and off the APUs on the 737, 757, 767 and 777. The pictures to the right and above are from that experience. The next week proved to be one filled with great experiences and interactions. I spent 3 days in the Maintenance Hangar learning about their operations, and hanging out with the mechanics. The first day I got a tour of the facility from the On-Duty Manager Fernando Whitehead. He made sure that I had a great time there through the observation of their operations and mingling with the mechanics and airplanes. It is quite impressive as to how the maintenance personnel work so intimately with the airplanes to ensure they are back in service in the most time effective manner with superior work. These mechanics are a wealth of knowledge and gave me a plethora of advice. They even tried to convince me to become a Mechanic. Lenny, Frank, Brian and Marlene were very welcoming, accommodating and made my stay there quite enjoyable. The picture to the left is from the 757 engine undergoing some maintenance.

The next week proved to be one filled with great experiences and interactions. I spent 3 days in the Maintenance Hangar learning about their operations, and hanging out with the mechanics. The first day I got a tour of the facility from the On-Duty Manager Fernando Whitehead. He made sure that I had a great time there through the observation of their operations and mingling with the mechanics and airplanes. It is quite impressive as to how the maintenance personnel work so intimately with the airplanes to ensure they are back in service in the most time effective manner with superior work. These mechanics are a wealth of knowledge and gave me a plethora of advice. They even tried to convince me to become a Mechanic. Lenny, Frank, Brian and Marlene were very welcoming, accommodating and made my stay there quite enjoyable. The picture to the left is from the 757 engine undergoing some maintenance. I got the opportunity to taxi a 777 from the hangar to the gate as it was being returned to service and later that day a 757 also. The picture to the right is what the centerline looks like from the FO’s seat as you are taxing. Saudi Arabia usually parks at our hanger along with British Airways during their prolonged ground time. I was fortunate enough to get to do a walk around of these airplanes and get up close and personal with them. The mechanics explained a lot of things about these aircraft that I had never known before, such as if the 777 were to lose an engine, it could still do a full Autoland. The pictures below are from that experience:

I got the opportunity to taxi a 777 from the hangar to the gate as it was being returned to service and later that day a 757 also. The picture to the right is what the centerline looks like from the FO’s seat as you are taxing. Saudi Arabia usually parks at our hanger along with British Airways during their prolonged ground time. I was fortunate enough to get to do a walk around of these airplanes and get up close and personal with them. The mechanics explained a lot of things about these aircraft that I had never known before, such as if the 777 were to lose an engine, it could still do a full Autoland. The pictures below are from that experience:

needed to be worked on immediately and expeditiously so as to prevent delays. The hangar was of a slower rate as the aircraft there needed larger maintenance requirement and were out of service. It was quite enlightening to see the difference in operations and a great learning experience but at the same time fun. The mechanics were also going to do a manual start of the 737 CFM-56 engine, but unfortunately I could see that as it was too dangerous.

needed to be worked on immediately and expeditiously so as to prevent delays. The hangar was of a slower rate as the aircraft there needed larger maintenance requirement and were out of service. It was quite enlightening to see the difference in operations and a great learning experience but at the same time fun. The mechanics were also going to do a manual start of the 737 CFM-56 engine, but unfortunately I could see that as it was too dangerous. Later that day I observed the operations at the Engine Bay in the hangar. Here is where they host a few spare engines, APUs and work on engines that have issues. It was so much fun as it brought back a lot of memories and information that I have learned in Turbines class at ERAU. I was able to go around the engines and find all the major parts and understand their importance. ERAU has educated me so well that it was quite easy understanding the engines, especially when the mechanics explained parts and concepts to me. I even got to participate in the Anniversary Party of a few mechanics who were celebrating their 20-25 year milestones at AA. The pictures to the left and above are from my time there.

Later that day I observed the operations at the Engine Bay in the hangar. Here is where they host a few spare engines, APUs and work on engines that have issues. It was so much fun as it brought back a lot of memories and information that I have learned in Turbines class at ERAU. I was able to go around the engines and find all the major parts and understand their importance. ERAU has educated me so well that it was quite easy understanding the engines, especially when the mechanics explained parts and concepts to me. I even got to participate in the Anniversary Party of a few mechanics who were celebrating their 20-25 year milestones at AA. The pictures to the left and above are from my time there. In the afternoon, I stayed an hour after work to help the mechanics get a 737 back into service. There was brake line that needed to be changed on the left main gear along with an engine test. I was quite excited to help them accomplish this task. After we changed the brake line, the manuals required that the gear be swung to ensure proper operation. This was here I came in to the rescue! I had to hoist the airplane up into the air so that the gear could be cycled. The picture to the right proved it.

In the afternoon, I stayed an hour after work to help the mechanics get a 737 back into service. There was brake line that needed to be changed on the left main gear along with an engine test. I was quite excited to help them accomplish this task. After we changed the brake line, the manuals required that the gear be swung to ensure proper operation. This was here I came in to the rescue! I had to hoist the airplane up into the air so that the gear could be cycled. The picture to the right proved it. Actually we just jacked the airplane up but it was a good photo opportunity. After that, we taxied the airplane out of the hangar and did an engine run up. That was really fun and REAL! Not like the simulator but an actual engine start. The next day I stayed almost 2 hours after work to help get a 757 back into service after a line check. Talk about putting in over time. These mechanics are so dedicated it is unbelievable. They are passionate about their jobs and so motivated. I also spent a few hours in the Maintenance Training Department. I got some training on the Computer Based Training Systems and it so happens that the manager of this department knows my parents. Small world huh! The pictures to the left and below are from the 737 gear well and cockpit:

Actually we just jacked the airplane up but it was a good photo opportunity. After that, we taxied the airplane out of the hangar and did an engine run up. That was really fun and REAL! Not like the simulator but an actual engine start. The next day I stayed almost 2 hours after work to help get a 757 back into service after a line check. Talk about putting in over time. These mechanics are so dedicated it is unbelievable. They are passionate about their jobs and so motivated. I also spent a few hours in the Maintenance Training Department. I got some training on the Computer Based Training Systems and it so happens that the manager of this department knows my parents. Small world huh! The pictures to the left and below are from the 737 gear well and cockpit: The Maintenance Crew is an amazing group of people and I had a blast with them. The picture to the right is just a small group of the wonderful people who ensure that the airplanes are well kept, maintained and safe.

The Maintenance Crew is an amazing group of people and I had a blast with them. The picture to the right is just a small group of the wonderful people who ensure that the airplanes are well kept, maintained and safe. e to communicate quite easily with the dispatchers as all the knowledge came rushing back. ERAU’s training like I always say is the BEST!

e to communicate quite easily with the dispatchers as all the knowledge came rushing back. ERAU’s training like I always say is the BEST! When I returned to NY on Friday, AA was celebrating it One World Alliance Anniversary with JAL. I got to partake in the festivities. There was a cultural show, amazing food and giveaways. AA also had their 777 One World Series on display. Once again I saw a photo opportunity. I may be going to Japan in September now.

When I returned to NY on Friday, AA was celebrating it One World Alliance Anniversary with JAL. I got to partake in the festivities. There was a cultural show, amazing food and giveaways. AA also had their 777 One World Series on display. Once again I saw a photo opportunity. I may be going to Japan in September now. The pictures to the right and above are from the party. As you can tell the past two weeks have been quite packed, fun and exciting. I can’t wait to continue learning and experiencing. Next week I’ll be in Dallas for a few days for flight training, a luncheon and when I return to JFK I’ll be spending some time with the MOD of Flight Service hoping from aircraft to aircraft learning about their operations. This weekend I’ll be heading to New Jersey to spend some time with my good friend

The pictures to the right and above are from the party. As you can tell the past two weeks have been quite packed, fun and exciting. I can’t wait to continue learning and experiencing. Next week I’ll be in Dallas for a few days for flight training, a luncheon and when I return to JFK I’ll be spending some time with the MOD of Flight Service hoping from aircraft to aircraft learning about their operations. This weekend I’ll be heading to New Jersey to spend some time with my good friend The past two weeks have been so hectic, traveling back and forth to Dallas. I even almost accidentally went to Narita, Japan but that’s another story. My seventh week on the internship was somewhat slow. Most of the time was spent in the office going to meetings and learning about general airport operations. It is definitely amazing to see how much input is needed to efficiently run an airport.

The past two weeks have been so hectic, traveling back and forth to Dallas. I even almost accidentally went to Narita, Japan but that’s another story. My seventh week on the internship was somewhat slow. Most of the time was spent in the office going to meetings and learning about general airport operations. It is definitely amazing to see how much input is needed to efficiently run an airport. The best part of this internship I’d have to say is the interaction with the pilots. I probably chat with about 50 pilots daily and they all have advice for me. It is great to be surrounded by such an intelligent, supportive and fun group. Being a Safety Minor also, I got to meet some pilots who are on the AA Go Team, which are basically Accident Investigators. We were able to speak about things related to Accident Investigation and I learned so much. After taking SF330- Aircraft Accident Investigation class at ERAU, I was able to hold a conversation with the investigators and relate to some of the things they were speaking about. It may be something I’d like to pursue in the future.

The best part of this internship I’d have to say is the interaction with the pilots. I probably chat with about 50 pilots daily and they all have advice for me. It is great to be surrounded by such an intelligent, supportive and fun group. Being a Safety Minor also, I got to meet some pilots who are on the AA Go Team, which are basically Accident Investigators. We were able to speak about things related to Accident Investigation and I learned so much. After taking SF330- Aircraft Accident Investigation class at ERAU, I was able to hold a conversation with the investigators and relate to some of the things they were speaking about. It may be something I’d like to pursue in the future. American Eagle Pilot and the other an intern from Alaska Airlines. We hardly slept so that’s a testament of how much fun we had. The pictures to the left and above were from that trip. The one from the air shows the Grand Canyon from about 38,000 feet. I returned to NY on the Saturday and then met up with my good friend on Sunday for some fun in the city. It was an amazing weekend.

American Eagle Pilot and the other an intern from Alaska Airlines. We hardly slept so that’s a testament of how much fun we had. The pictures to the left and above were from that trip. The one from the air shows the Grand Canyon from about 38,000 feet. I returned to NY on the Saturday and then met up with my good friend on Sunday for some fun in the city. It was an amazing weekend. The eight-week began with so much 777s. This aircraft surrounded me. On Monday morning by 9:30 I had already preflighted two 777s. I almost made it to Narita also. That would have been funny to explain to my boss. I was chilling in the cockpit with the pilots after the preflight and the flight attendant almost closed the door with me in the aircraft. I wished she did! When I went back to the office I met two 777-check pilots and later that day had lunch with a 777 captain who was heading to Brazil later that night. The wealth of advice and knowledge you can gain from these pilots is unbelievable. The picture to the right is from the preflight and the picture below is of me enjoying the 777 First Class with a few of the crewmembers.

The eight-week began with so much 777s. This aircraft surrounded me. On Monday morning by 9:30 I had already preflighted two 777s. I almost made it to Narita also. That would have been funny to explain to my boss. I was chilling in the cockpit with the pilots after the preflight and the flight attendant almost closed the door with me in the aircraft. I wished she did! When I went back to the office I met two 777-check pilots and later that day had lunch with a 777 captain who was heading to Brazil later that night. The wealth of advice and knowledge you can gain from these pilots is unbelievable. The picture to the right is from the preflight and the picture below is of me enjoying the 777 First Class with a few of the crewmembers. The following weeks will be so much more involving as the Chief Pilot asked me to give him my wish list and he will allow me to do everything on it. Next week I will be heading to the FAA Tower at JFK, and also working 2 night shifts at the Ramp Control Tower. In the near future I will be going to the New York ARTCC, have an airport and ARFF Tour, preflight Air Berlin’s A330, JAL 747-400, Finnair A340, and Qatar 777-300ER. I’ll also be working in the Maintenance Hanger too. So stay tuned and see all the pictures… Happy 4th July!

The following weeks will be so much more involving as the Chief Pilot asked me to give him my wish list and he will allow me to do everything on it. Next week I will be heading to the FAA Tower at JFK, and also working 2 night shifts at the Ramp Control Tower. In the near future I will be going to the New York ARTCC, have an airport and ARFF Tour, preflight Air Berlin’s A330, JAL 747-400, Finnair A340, and Qatar 777-300ER. I’ll also be working in the Maintenance Hanger too. So stay tuned and see all the pictures… Happy 4th July!

These past two weeks have been really exciting and amazing. There was so much I saw, did and learned. This Internship has opened my eyes to the world of the airlines. Many of the things we learn in school I am seeing in full practice. Just this past week I attended a meeting on behalf of the American Airlines Flight Department with Occupational Safety and Health Administration (OSHA). The safety culture here at AA is very unique and strong. Terms and practices learned in Human Factors and Safety classes are being implemented right in my field of view. As I kept saying, the education at ERAU is unmatched and has prepared me very well for the future in this industry. The OSHA meeting focused on electricity safety and safety audits.

These past two weeks have been really exciting and amazing. There was so much I saw, did and learned. This Internship has opened my eyes to the world of the airlines. Many of the things we learn in school I am seeing in full practice. Just this past week I attended a meeting on behalf of the American Airlines Flight Department with Occupational Safety and Health Administration (OSHA). The safety culture here at AA is very unique and strong. Terms and practices learned in Human Factors and Safety classes are being implemented right in my field of view. As I kept saying, the education at ERAU is unmatched and has prepared me very well for the future in this industry. The OSHA meeting focused on electricity safety and safety audits. The really fun parts of the internship are still ahead but over the past two weeks I was given the opportunity to preflight the 737-800 and MD-80 aircraft. It was quite a thrill! Two very different aircraft in terms of design, performance and handling characteristics but quite similar in operations. The pictures to the right and below are from the preflights. There was so much to learn and see with these two airplanes and the pilots were very knowledgeable and willing to teach me. As I write this journal right now, I am on my way to Chicago in a MD-80 that I preflighted and programmed the FMS for. Amazing!

The really fun parts of the internship are still ahead but over the past two weeks I was given the opportunity to preflight the 737-800 and MD-80 aircraft. It was quite a thrill! Two very different aircraft in terms of design, performance and handling characteristics but quite similar in operations. The pictures to the right and below are from the preflights. There was so much to learn and see with these two airplanes and the pilots were very knowledgeable and willing to teach me. As I write this journal right now, I am on my way to Chicago in a MD-80 that I preflighted and programmed the FMS for. Amazing! The picture to the left is from the AA ramp control at LGA, where I began my Ramp Operations Training. It really brings to light the importance of CRM and the training that Riddle has instilled into me. On that day, I was giving an American 757 clearance to push back for its flight to MIA while talking to Flight Ops. The amount of people and work that goes into a flight from one gate to another gate is remarkable and each one of them must be appreciated.

The picture to the left is from the AA ramp control at LGA, where I began my Ramp Operations Training. It really brings to light the importance of CRM and the training that Riddle has instilled into me. On that day, I was giving an American 757 clearance to push back for its flight to MIA while talking to Flight Ops. The amount of people and work that goes into a flight from one gate to another gate is remarkable and each one of them must be appreciated. On the right is a picture of the ORD crew that I was chatting with one day. I just went to their cockpit, introduced myself and chatted a bit. Sometimes you never know who you might find, and that day, the Captain was a Riddle Grad., and the FO is a Union Rep. Looks like I’ll be chilling with the pilots at the Jets game in July just from stopping by and saying ‘Hi, I’m the intern Ryan….’

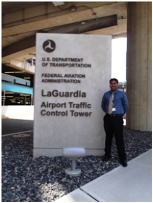

On the right is a picture of the ORD crew that I was chatting with one day. I just went to their cockpit, introduced myself and chatted a bit. Sometimes you never know who you might find, and that day, the Captain was a Riddle Grad., and the FO is a Union Rep. Looks like I’ll be chilling with the pilots at the Jets game in July just from stopping by and saying ‘Hi, I’m the intern Ryan….’ Last week I completed my SIDA Training and will be the first AA intern who has ramp access at both LGA and JFK. Also, I was very fortunate to get a tour of the LGA FAA Control Tower. There I saw many practices that I have studied while doing my minor in ATC. It was so amazing to see the training in full practice.

Last week I completed my SIDA Training and will be the first AA intern who has ramp access at both LGA and JFK. Also, I was very fortunate to get a tour of the LGA FAA Control Tower. There I saw many practices that I have studied while doing my minor in ATC. It was so amazing to see the training in full practice. The picture on the right is from the tower. As you can see the queues are quite long at LGA for take-off as it is on of the busiest airports in the country. Today, I was 15th in line for take-off but it looks that we’ll be landing in ORD on time.

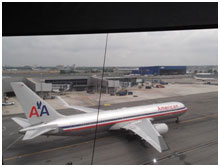

The picture on the right is from the tower. As you can see the queues are quite long at LGA for take-off as it is on of the busiest airports in the country. Today, I was 15th in line for take-off but it looks that we’ll be landing in ORD on time. The picture on the left is from my office at JFK. You have to love your job when you come to work with a view like this everyday. When I have lunch the view is a queue for take-off with 747s, A380, A340s and 777s. I just can’t wait to be actually flying one of them.

The picture on the left is from my office at JFK. You have to love your job when you come to work with a view like this everyday. When I have lunch the view is a queue for take-off with 747s, A380, A340s and 777s. I just can’t wait to be actually flying one of them. The best part of the Internship is the travel benefits. There are so many places to go, so much to see, do and learn. These two weeks I have been to Fort Lauderdale, Miami and now Chicago. On my way to FLL I met a FedEx MD-11 FO who gave me some good advice and information about Cargo Flying and flying the MD-11. The picture to the left was from my first non-rev flight.

The best part of the Internship is the travel benefits. There are so many places to go, so much to see, do and learn. These two weeks I have been to Fort Lauderdale, Miami and now Chicago. On my way to FLL I met a FedEx MD-11 FO who gave me some good advice and information about Cargo Flying and flying the MD-11. The picture to the left was from my first non-rev flight. I was very skeptical as to what the American Airlines Internship would have planned for me but to my surprise and excitement, I would be having the time of my life. I was unable to attend the orientation process on the 13th and 14th of May as I was graduating but I was able to make the second class on May 16th and 17th. The picture to the left was taken at the AA Flight Academy in Dallas just before Orientation commenced. There are so many people that make an Airline run efficiently and at American it is quite evident. The people are great and friendly and they work together to ensure the airline is at its best.

I was very skeptical as to what the American Airlines Internship would have planned for me but to my surprise and excitement, I would be having the time of my life. I was unable to attend the orientation process on the 13th and 14th of May as I was graduating but I was able to make the second class on May 16th and 17th. The picture to the left was taken at the AA Flight Academy in Dallas just before Orientation commenced. There are so many people that make an Airline run efficiently and at American it is quite evident. The people are great and friendly and they work together to ensure the airline is at its best. The Dispatcher, Stephen, also taught me how they choose certain routes, their planned NAR’s, NAT Tracks and European Routes. We chatted about ETOPS, reporting points such as Shemya in Alaska and the fact that AA can get a 757 from ORD to LHR. I learned so much from just an hour with them. This just shows how superior ERAU’s course work and training is!

The Dispatcher, Stephen, also taught me how they choose certain routes, their planned NAR’s, NAT Tracks and European Routes. We chatted about ETOPS, reporting points such as Shemya in Alaska and the fact that AA can get a 757 from ORD to LHR. I learned so much from just an hour with them. This just shows how superior ERAU’s course work and training is! On my first day at LGA little did I know that I would be having the best first day ever! Melanie Rodriguez, one of the friendliest AA employees, greeted me at LGA. She took me to my office where I met my supervisor, Ellen Barbaro. Melanie oriented me around the facilities and gave me access codes and keys to different departments and rooms.

On my first day at LGA little did I know that I would be having the best first day ever! Melanie Rodriguez, one of the friendliest AA employees, greeted me at LGA. She took me to my office where I met my supervisor, Ellen Barbaro. Melanie oriented me around the facilities and gave me access codes and keys to different departments and rooms. After I returned from the Tower, I ran into a 757 Crew who gave me a tour of the pilot operation. They taught about their flight release, how to read it and what to pay special attention to. I had previous knowledge from classes, so it was quite easy for me to read it. They were impressed by how much I knew and complemented ERAU’s training. The FO was a Riddle grad also. They then took me on the preflight of the 757and that was the highlight of my first day. Not only did I learn about how to preflight a 757 but I also got to program the FMS. Riddle has prepared me very well for this. After taking AS435, programming the FMS came with ease. It was so much fun to actually put what I learned in class to practical use. The pictures below are from the preflight.

After I returned from the Tower, I ran into a 757 Crew who gave me a tour of the pilot operation. They taught about their flight release, how to read it and what to pay special attention to. I had previous knowledge from classes, so it was quite easy for me to read it. They were impressed by how much I knew and complemented ERAU’s training. The FO was a Riddle grad also. They then took me on the preflight of the 757and that was the highlight of my first day. Not only did I learn about how to preflight a 757 but I also got to program the FMS. Riddle has prepared me very well for this. After taking AS435, programming the FMS came with ease. It was so much fun to actually put what I learned in class to practical use. The pictures below are from the preflight. The second day was filled with chatting with pilots and crewmembers. I met Chief Pilot, Mark Cronin, and it so happens that we share the same birthday. He’s a really nice and friendly guy. The second day was as eventful as the first. I leaned so much about the company and pilot procedures. I received my 737 checklists and calculations/limitations information.

The second day was filled with chatting with pilots and crewmembers. I met Chief Pilot, Mark Cronin, and it so happens that we share the same birthday. He’s a really nice and friendly guy. The second day was as eventful as the first. I leaned so much about the company and pilot procedures. I received my 737 checklists and calculations/limitations information. My internship at the Prosecutor’s Office has really proved to be an exceptional experience! For one, I was able to take a tour of the Ocean County Jail last week. For any of you that watch the Jersey Shore television show, this is the jail that they take one of the cast members to in the first season. In addition to seeing the jail, and feeling extremely unwelcome by the inmates there, I was able to see “Pauly D” of the Jersey Shore, while on a ride-along with the Sea Side Heights Police Department. The cast member “Snookie” was also arrested the Friday night I was there. Even though I was not involved at all with these people, I still thought it was pretty cool to have “been there.” Going back to the topic of jail, I am not sure how many of you have been to jail (hopefully none), but it really is an awful place. No matter how many T.V. shows you may have seen, or stories you have heard, nothing can replicate the shear feeling of being inside a jail. Typically people avoid places of high crime where criminals live during their daily lives, but in jail, this is the home to many of those criminals. Aside from the whistling, the sneers, cursing, yelling, etc. the jail was a great educational experience.

My internship at the Prosecutor’s Office has really proved to be an exceptional experience! For one, I was able to take a tour of the Ocean County Jail last week. For any of you that watch the Jersey Shore television show, this is the jail that they take one of the cast members to in the first season. In addition to seeing the jail, and feeling extremely unwelcome by the inmates there, I was able to see “Pauly D” of the Jersey Shore, while on a ride-along with the Sea Side Heights Police Department. The cast member “Snookie” was also arrested the Friday night I was there. Even though I was not involved at all with these people, I still thought it was pretty cool to have “been there.” Going back to the topic of jail, I am not sure how many of you have been to jail (hopefully none), but it really is an awful place. No matter how many T.V. shows you may have seen, or stories you have heard, nothing can replicate the shear feeling of being inside a jail. Typically people avoid places of high crime where criminals live during their daily lives, but in jail, this is the home to many of those criminals. Aside from the whistling, the sneers, cursing, yelling, etc. the jail was a great educational experience. The other major highlight of my past two weeks was being able to do a ride along with the New Jersey State Police. Thankfully my boss was able to set up the NJSP taking me out and showing me the “ropes” at Troop D, which covers the Turnpike. For a link to the NJSP Troop Map,

The other major highlight of my past two weeks was being able to do a ride along with the New Jersey State Police. Thankfully my boss was able to set up the NJSP taking me out and showing me the “ropes” at Troop D, which covers the Turnpike. For a link to the NJSP Troop Map,  Time seems to be going by so fast here, I can’t believe I’ve only one and a half more months here. I’m really going to miss Munich and MTU when I have to go back to Daytona for class, but right now I miss home too so it’ll be good to go back to the States. I’ve been insanely busy at MTU recently. We have a new intern in my office as well. She’s a first-year engineering student from France, but she talks with us in English. Things are a bit new to her so, for the most part, she’s starting out how I started my internship, scanning papers and updating databases, but she seems to be picking everything up pretty quickly and it must be harder for her since English isn’t her first language.

Time seems to be going by so fast here, I can’t believe I’ve only one and a half more months here. I’m really going to miss Munich and MTU when I have to go back to Daytona for class, but right now I miss home too so it’ll be good to go back to the States. I’ve been insanely busy at MTU recently. We have a new intern in my office as well. She’s a first-year engineering student from France, but she talks with us in English. Things are a bit new to her so, for the most part, she’s starting out how I started my internship, scanning papers and updating databases, but she seems to be picking everything up pretty quickly and it must be harder for her since English isn’t her first language. As for me, I’m getting ready for an FAA audit of MTU’s software systems the first week of August (which hopefully I’ll get to sit in on as well, sitting in on the Pratt and Whitney audit was interesting). From what I understand, it will be the same kind of audit, but I’m still reviewing everything and revising the presentation we made for Pratt. Right now there’s not a lot of work with CAD to do, so I’m mostly just helping my boss with some of the tasks he’s been put in charge of. We still haven’t made any concrete conclusions about acceptable tolerance variations for parts being manufactured in Poland because they want to run more Try-Outs which take time, so for now that project seems to be stalled. So aside from working on the FAA audit, I’ve been collecting information and analyzing data taken from two of the shop floor controller machines (the machines that create the engine parts) that have been operating with an upgraded software/sensor system.

As for me, I’m getting ready for an FAA audit of MTU’s software systems the first week of August (which hopefully I’ll get to sit in on as well, sitting in on the Pratt and Whitney audit was interesting). From what I understand, it will be the same kind of audit, but I’m still reviewing everything and revising the presentation we made for Pratt. Right now there’s not a lot of work with CAD to do, so I’m mostly just helping my boss with some of the tasks he’s been put in charge of. We still haven’t made any concrete conclusions about acceptable tolerance variations for parts being manufactured in Poland because they want to run more Try-Outs which take time, so for now that project seems to be stalled. So aside from working on the FAA audit, I’ve been collecting information and analyzing data taken from two of the shop floor controller machines (the machines that create the engine parts) that have been operating with an upgraded software/sensor system. It’s a LOT of data, charts, graphs, etc to go through and the reports are ALL in German. MTU wants to look into upgrading its machines to this software in the future and is trying to determine the benefits. It seems pretty promising…it measures the power being used by the machining tool and the force it is exerting on the part and determines the variance of these while the part feature is being machined. The (very) basic idea is that the greater the variance of the power/force used during machining, the more likely the tool is to break. MTU hopes to save money by preventing tool breaks which, when they occur, can damage parts to the point where they must be scrapped ($50,000~ worth of scrap approx.) or cost money because the damaged part must be reworked.

It’s a LOT of data, charts, graphs, etc to go through and the reports are ALL in German. MTU wants to look into upgrading its machines to this software in the future and is trying to determine the benefits. It seems pretty promising…it measures the power being used by the machining tool and the force it is exerting on the part and determines the variance of these while the part feature is being machined. The (very) basic idea is that the greater the variance of the power/force used during machining, the more likely the tool is to break. MTU hopes to save money by preventing tool breaks which, when they occur, can damage parts to the point where they must be scrapped ($50,000~ worth of scrap approx.) or cost money because the damaged part must be reworked. My boss and I met today with the engineer who has been taking the data from these machines and who wrote the reports. The first thing my boss told me was “Take notes for later,” then he proceeded to talk in really fast German with the engineer. Very fun. Luckily, I managed to get a few words in and get some sparing information in English which will have to be enough for me to draw my conclusion on the feasibility of this software (it costs $10,000~/machine). If not, I’m going engineer hunting on the shop floor lines tomorrow…

My boss and I met today with the engineer who has been taking the data from these machines and who wrote the reports. The first thing my boss told me was “Take notes for later,” then he proceeded to talk in really fast German with the engineer. Very fun. Luckily, I managed to get a few words in and get some sparing information in English which will have to be enough for me to draw my conclusion on the feasibility of this software (it costs $10,000~/machine). If not, I’m going engineer hunting on the shop floor lines tomorrow… Anyways, that’s what’s been happening at work…but for a good 5 days since the last time I wrote I was in Paris! It was amazing. The last time I was in Paris I was with a tour group and we had to go where they went, when they went…it was so much better just being there by myself and making my own schedule. I mostly did the cliché tourist things anyways…climbed all the stairs of the Eiffel Tower (I wish you could climb to the top though…), saw the Statue of Liberty replica, saw the Mona Lisa in the Louvre, saw Notre Dame, saw the Sacre-Coeur, and the Catacombs. I took 6 years of French in Jr. High/High School so for the most part I could communicate, except I kept mixing German in my French…

Anyways, that’s what’s been happening at work…but for a good 5 days since the last time I wrote I was in Paris! It was amazing. The last time I was in Paris I was with a tour group and we had to go where they went, when they went…it was so much better just being there by myself and making my own schedule. I mostly did the cliché tourist things anyways…climbed all the stairs of the Eiffel Tower (I wish you could climb to the top though…), saw the Statue of Liberty replica, saw the Mona Lisa in the Louvre, saw Notre Dame, saw the Sacre-Coeur, and the Catacombs. I took 6 years of French in Jr. High/High School so for the most part I could communicate, except I kept mixing German in my French…  And I even got to go to Disneyland this time! It’s interesting seeing Disney here, I’m so used to Disney in Orlando. It’s strange how they mix English phrases into the rides and shows. The Tower of Terror was in English, the exact same audio as in Orlando Disney…it was kind of nice because it *almost* felt like being home.

And I even got to go to Disneyland this time! It’s interesting seeing Disney here, I’m so used to Disney in Orlando. It’s strange how they mix English phrases into the rides and shows. The Tower of Terror was in English, the exact same audio as in Orlando Disney…it was kind of nice because it *almost* felt like being home.